Hyundai Mobis Unveils Revolutionary EV Battery Cooling Technology to Prevent Overheating

As the demand for ultra-fast charging electric vehicles (EVs) grows, so does the need for advanced thermal management systems to prevent battery overheating. In a groundbreaking development, Hyundai Mobis has introduced a new battery cell cooling material called the Pulsating Heat Pipe (PHP), designed to enhance heat dissipation and improve the safety and efficiency of EV batteries.

This innovative technology not only addresses the challenges of overheating during rapid charging but also promises to significantly reduce charging times, making it a game-changer in the EV industry.

What is the Pulsating Heat Pipe (PHP)?

The Pulsating Heat Pipe is a cutting-edge cooling material made from aluminium alloy and refrigerant, strategically placed between battery cells to lower internal temperatures during high-stress scenarios like ultra-fast charging.

How It Works:

- Heat Dissipation: The PHP uses the vibration and circulation of refrigerant within its structure to diffuse heat efficiently.

- High Heat Transfer Performance: It boasts 10 times the heat transfer efficiency of standard aluminium cooling plates, rapidly moving heat from overheated battery cells to the exterior.

- Gravity-Resistant Design: Unlike traditional heat pipes, the PHP maintains its performance even in high-speed moving vehicles, ensuring consistent cooling under all conditions.

Why Is This Technology Important?

1. Preventing Overheating During Ultra-Fast Charging

Ultra-fast charging generates significant heat, which can degrade battery performance and pose safety risks. The PHP stabilizes the battery’s internal temperature, ensuring safe and efficient charging.

2. Reducing Charging Times

By effectively managing heat, the PHP allows EVs to handle higher charging currents, potentially reducing charging times and making EVs more convenient for consumers.

3. Enhancing Battery Longevity

Overheating is a major cause of battery degradation. The PHP’s ability to maintain stable temperatures helps extend the lifespan of EV batteries, reducing long-term costs for users.

Comparison with Standard Aluminium Cooling Plates

In a heat dissipation performance test, Hyundai Mobis compared the PHP to a standard aluminium cooling plate. The results revealed a temperature difference of nearly 20 degrees, highlighting the PHP’s superior cooling capabilities.

This significant improvement ensures that EV batteries remain within safe operating temperatures, even during the most demanding charging and driving conditions.

How Hyundai Mobis Integrated PHP into EV Batteries

Battery System Architecture

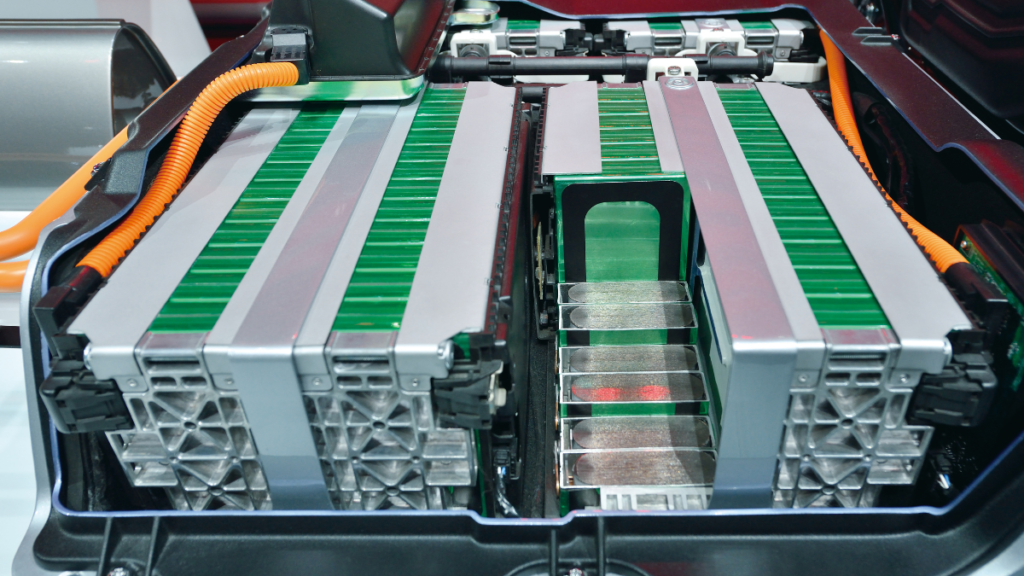

EV battery systems are typically composed of:

- Battery Cells: The core components that generate electrical energy.

- Battery Modules (BMA): Stacks of battery cells.

- Battery Management Systems (BMS): Electronics that monitor and manage battery performance.

Hyundai Mobis successfully integrated PHPs between individual battery cells. The PHPs transfer heat from the cells to cooling blocks, stabilizing the temperature at the module level.

Innovative Manufacturing Process

To make the PHPs practical for large-scale production, Hyundai Mobis developed a press process that simplifies manufacturing and reduces costs. Key advancements include:

- Ultra-Thin Design: PHPs are just 0.8mm thick, significantly thinner than standard heat pipes (6mm), allowing for seamless integration into EV battery systems.

- Larger Surface Area: The increased surface area enhances heat dissipation, further improving cooling efficiency.

Impact on the EV Industry

Hyundai Mobis’ PHP technology is poised to revolutionize the EV market by addressing one of the most critical challenges—thermal management.

1. Promoting EV Adoption

By improving battery safety, reducing charging times, and enhancing performance, the PHP technology makes EVs more appealing to consumers, accelerating the transition to electric mobility.

2. Cost-Effective Manufacturing

The simplified production process and reduced material costs make the PHP a viable solution for mass-market EVs, ensuring that advanced cooling technology is not limited to premium models.

3. Supporting Future Mobility

As EVs become more powerful and charging speeds increase, innovations like the PHP will play a crucial role in ensuring that battery systems can handle the demands of next-generation vehicles.

A Game-Changer for EV Batteries

Hyundai Mobis’ Pulsating Heat Pipe technology represents a significant leap forward in EV battery cooling. By offering superior heat dissipation, reducing charging times, and enhancing battery safety, the PHP is set to redefine thermal management in the EV industry.

As Hyundai Mobis works toward commercializing this technology, it is clear that the company is committed to driving innovation and maintaining its competitive edge in the future mobility market. With advancements like the PHP, the EV industry is one step closer to achieving faster, safer, and more efficient electric vehicles.