In a groundbreaking development for electric vehicle technology, China’s GAC Group has reportedly built the country’s first-ever production line capable of making large (60 Ah+) all-solid-state electrical vehicle battery cells, putting China into the early industrialization stage of solid-state tech—something Japan’s Toyota and a few US/Korean startups have been chasing for years.

Table of Contents

GAC Solid-State Battery Breakthrough

| Specification | Details |

|---|---|

| Manufacturer | GAC Group (China) |

| Battery Capacity | 60+ Ah (Ampere-hours) |

| Production Status | Pilot line (small-batch testing) |

| Energy Density | Nearly 2x conventional batteries |

| Range Potential | 1,000 km (vs. 500 km current) |

| Areal Capacity | 7.7 mAh/cm² |

| Temperature Stability | 300–400°C |

| Vehicle Testing | 2026 |

| Mass Production | 2027–2030 |

| Comparison | Most EV cells: 40–50 Ah |

Understanding the Technology Leap

An ampere-hour (Ah) is a unit of electric charge that measures a battery’s capacity, representing the amount of current it can deliver over time, with 60 Ah meaning these batteries can deliver 60 amps for one hour, or 6 amps for 10 hours. Most EV pouch cells today range between 40–50 Ah, making GAC’s achievement significant.

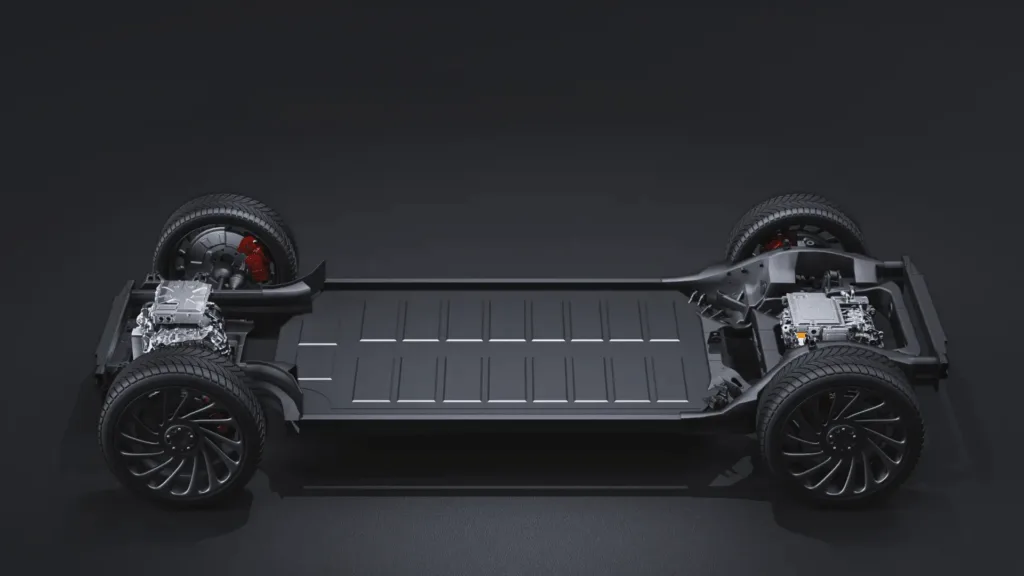

Such batteries will have higher pack energy, require fewer cells because each one stores more, and potentially lower pack cost and weight, which would be a huge deal for large-format EV cells.

Solid-State vs. Conventional Batteries

Conventional lithium-ion cells use a liquid electrolyte, while solid-state batteries use a solid electrolyte, with such batteries tending to have higher energy densities (more energy per kg or liter) and improved thermal safety (less fire risk).

This allows for faster charging and enables them to work at higher temperatures, with GAC claiming 300–400°C stability—a dramatic improvement over conventional batteries that typically withstand only around 200°C.

Doubled Range Potential

GAC claims nearly double the energy density of current cells, which, if true, is huge—that’s why they say a 311-mile (500 km) EV today could go 621 miles (1,000 km) on the same-sized battery pack.

GAC’s research director, Qi Hongzhong, said the energy density of the new solid-state cells is nearly double that of conventional batteries, with vehicles currently capable of 500 km (~310 miles) on a single charge potentially reaching more than 1,000 km (~620 miles) with these cells.

Critical Manufacturing Breakthrough

According to GAC, the new battery line can achieve an “areal capacity” of 7.7 mAh/cm², with traditional liquid-electrolyte lines typically only ever achieving up to 5 mAh/cm².

This number matters because high areal capacity is the hardest manufacturing challenge in solid-state batteries—it determines whether you can make thick enough electrodes to store lots of energy without cracking or failing during production.

If GAC has really proven this on a pilot line, it suggests its solid electrolyte interface is stable and its dry-process electrode manufacturing works, suggesting that industrial scaling is technically feasible in the future.

Advanced Manufacturing Process

The company is using a “dry” anode production process that combines slurry mixing, coating, and rolling into a single step, which reportedly improves manufacturing efficiency and reduces energy consumption.

While traditional liquid batteries require three separate steps—slurry preparation, coating and calendaring—the dry process directly integrates these steps into a single operation, reducing energy consumption while improving efficiency.

Timeline to Market

GAC plans to start small-batch vehicle testing of its new battery sometime in 2026, then hoping to ramp up production for commercial delivery between 2027 and 2030. These milestones depend on market reaction, mass adoption, scaling of supply chain solid electrolytes, and costs falling to competitive levels.

Qi Hongzhong, head of new-energy power R&D at GAC’s advanced platform technology institute, said GAC plans to begin small-scale vehicle installation tests next year and gradually move to mass production between 2027 and 2030.

China’s Broader Solid-State Push

GAC isn’t alone in this race. China’s largest EV maker, BYD, said that the company plans to begin small-scale production of sulfide-based all-solid-state batteries by 2027, and incorporate them into its mainstream EV models by 2030.

Gotion High-Tech, a leading battery maker, has launched the first road testing for its next-generation all-solid-state batteries, after completing the country’s first fully localized 0.2 gigawatt-hour pilot production line.

Automaker SAIC Motor Corp said on Sunday that its partner Qingtao has completed the main production line for an all-solid-state battery plant in Shanghai, and sample cells are expected to roll off the line by the end of the year.

Government Support Accelerating Progress

Industry sources said that Chinese authorities are preparing to expand efforts and introduce stronger policy and financial support for the research and development of all-solid-state batteries, with measures intended to accelerate and steer resources toward breakthroughs in materials, technical routes, safety performance, large-scale manufacturing and application.

Global Competitive Implications

This new pilot line shows that China is moving from lab-scale innovation to industrial-scale capability in solid-state batteries, positioning China to challenge Japanese, Korean, and US solid-state efforts.

GAC’s achievement represents a significant milestone in the global race to commercialize solid-state battery technology. While competitors like Toyota have long promised solid-state breakthroughs, China’s focus on rapid industrialization and pilot production lines demonstrates a pragmatic approach to bringing next-generation battery technology to market.

Challenges Ahead

Despite the breakthrough, significant hurdles remain. Manufacturing yield stability, cost of materials, supply chain development for solid-electrolyte components, and maintaining performance in real-world conditions all present challenges before mass commercialization becomes viable.

For comprehensive coverage of battery technology developments and EV innovations, visit India EV News. For technical deep-dives into solid-state battery technology, explore resources at Interesting Engineering.