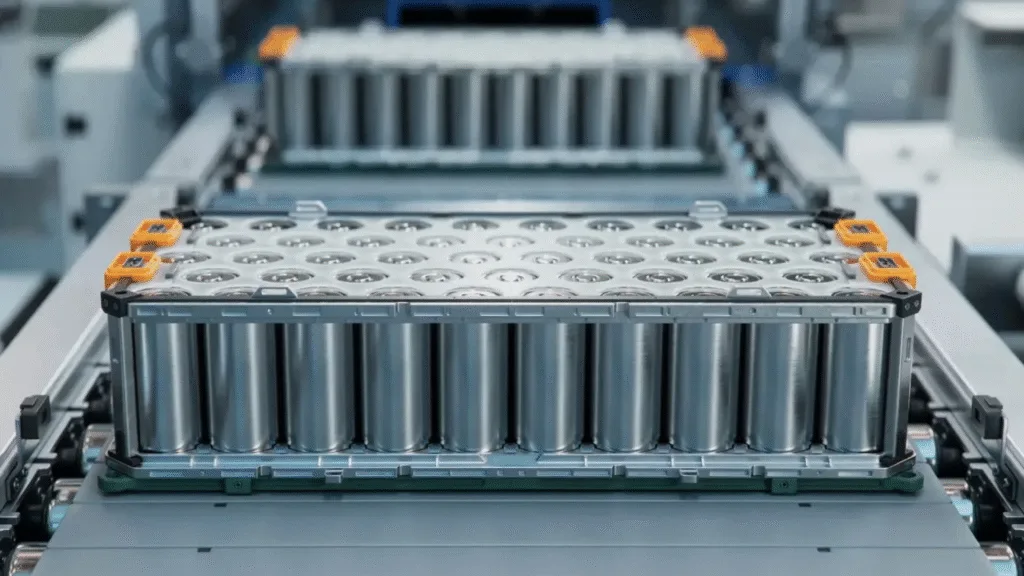

Silver-Ion EV, Imagine an electric vehicle battery that barely degrades after years of use. Korean researchers have 63just made this dream tangible with a revolutionary silver-ion coating technology that could finally unlock the full potential of next-generation lithium-metal batteries.

The breakthrough? Batteries maintaining over 96% capacity after 1,300 charge-discharge cycles—while operating stably for over 2,000 hours. This isn’t incremental progress; it’s a quantum leap that could double today’s EV range while dramatically extending battery lifespan.

Table of Contents

The Dendrite Problem That’s Plagued EVs

To understand why this matters, you need to know about dendrites—the silent killers of high-performance batteries.

During charging, lithium doesn’t always deposit evenly on the battery’s negative electrode. Instead, it forms tiny, tree-like metal structures that grow like cancer through the battery. Eventually, these dendrites:

- Pierce the separator between anode and cathode

- Cause dangerous short circuits

- Trigger overheating and potential explosions

- Drastically shorten battery life

This single issue has prevented lithium-metal batteries—which promise double the energy density of conventional lithium-ion cells—from reaching commercial viability.

The Silver Solution: Simple Yet Revolutionary

| Technology Aspect | Details |

|---|---|

| Innovation | Ultrathin silver-ion coating |

| Processing | Room temperature, atmospheric pressure |

| Components | Silver ions + trithioisocyanuric acid (TCA) |

| Advantage | No complex synthesis or high-temperature treatment |

Led by Professor Cho Jin-han from Korea University’s chemical and biological engineering department, the research team developed an elegantly simple solution. They alternate layers of silver ions and TCA on the electrode substrate using only a room-temperature solution process.

Here’s the magic: When the battery operates, silver ions naturally transform into silver nanoparticles. These nanoparticles act like tiny traffic controllers, guiding lithium atoms to spread uniformly across the electrode instead of clumping into dangerous dendrites.

Meanwhile, the TCA component creates a chemically stable matrix that prevents cracking or surface damage—even after thousands of cycles.

Performance That Changes Everything

| Metric | Result | Significance |

|---|---|---|

| Stable Operation | 2,000+ hours | Long-term reliability proven |

| Capacity Retention | 96% after 1,300 cycles | Minimal degradation over time |

| Safety | No dendrite formation | Eliminates explosion risk |

| Manufacturing | Room temperature process | Commercially viable production |

Traditional lithium-ion batteries in today’s EVs typically retain 80% capacity after 1,000 cycles—considered the industry standard. This new technology not only exceeds that benchmark but maintains superior performance across significantly more cycles.

Real-World Impact for EV Owners

What does 96% retention after 1,300 cycles mean for you?

If you charge your EV every three days, 1,300 cycles represents approximately 11 years of use. After over a decade, your battery would still have 96% of its original capacity. Compare that to current batteries that might degrade to 70-80% in the same timeframe.

Double the Energy Density: Lithium-metal batteries can theoretically store twice the energy of conventional lithium-ion cells. A 400-mile range EV could become an 800-mile range vehicle—without increasing battery size or weight.

Beyond EVs: The Broader Potential

Professor Cho emphasizes that this isn’t just about electric vehicles. The research team believes their approach could revolutionize multiple battery technologies:

- Sodium batteries: Cheaper, more abundant materials

- Zinc batteries: Enhanced safety profiles

- Grid-scale energy storage: Renewable energy stabilization

- Portable electronics: Longer-lasting devices

“In the future, it could evolve into a technology platform that can be extended to lithium and various metal batteries such as sodium and zinc,” Cho explained.

The Science Made Simple

The innovation works through precise chemical choreography:

- Application: Silver ions and TCA layers coat the electrode at room temperature

- Activation: During operation, silver ions convert to nanoparticles

- Guidance: Nanoparticles direct uniform lithium deposition

- Protection: TCA matrix prevents physical degradation

- Result: Smooth, safe, stable battery operation

Commercialization Timeline

While laboratory results are promising, the technology’s simplicity gives it a competitive advantage. Unlike methods requiring expensive nanoparticle synthesis or energy-intensive high-temperature treatments, this room-temperature solution process could integrate into existing manufacturing relatively quickly.

The researchers published their findings in the prestigious journal Advanced Materials, titled “High-performance dendrite-free lithium textile anodes using interfacial interaction-mediated ultrathin metal organic framework multilayers.”

The Bottom Line

This breakthrough addresses the fundamental barrier preventing next-generation batteries from reaching market. By solving the dendrite problem with an elegant, scalable solution, Korean researchers have potentially unlocked:

- Doubled EV range through higher energy density

- Extended battery lifespan with minimal degradation

- Enhanced safety eliminating explosion risks

- Commercial viability through simple manufacturing

The transition from laboratory to factory floor remains uncertain, but the performance metrics suggest this technology is remarkably close to real-world application standards.

For EV manufacturers racing to deliver longer range and better longevity, silver-ion coating could be the game-changing innovation they’ve been searching for.