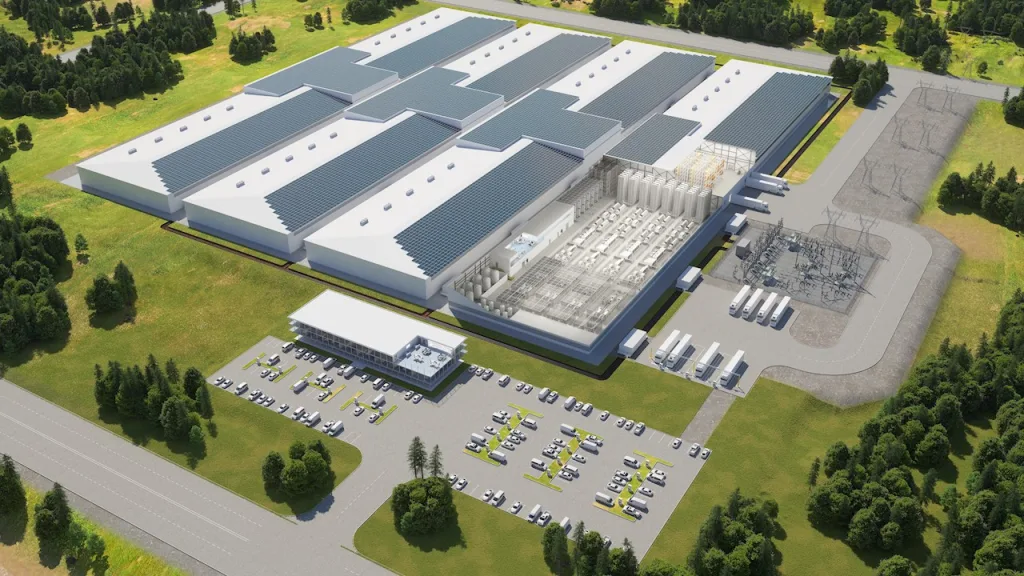

The landscape of electric vehicle manufacturing in the UK is about to undergo a revolutionary transformation with the construction of Britain’s largest EV battery plant. Tata Group’s battery business, Agratas, has shared updated plans for their £4 billion gigafactory in Somerset, marking a significant milestone in the UK’s journey toward automotive electrification and sustainability.

Gigafactory UK: Updated Plans Reveal Strategic Adjustments

Recent consultations with local communities have unveiled key modifications to the original gigafactory blueprint. The main production facility will now be 84 meters shorter than initially proposed, a change that Agratas executives explain will significantly reduce energy consumption, water usage, and the overall carbon footprint without compromising production capacity or employment opportunities.

“Despite a level of uncertainty in the market, we’re here making a big strategic bet in Somerset,” said Jefferson Weber, Agratas head of construction. “We really believe in this market, we’re bullish about it, and we think it’s the future of vehicle manufacturing.”

This optimistic outlook comes despite the facility’s opening being rescheduled to 2027, one year later than previously announced.

Electric Vehicle Manufacturing UK: Economic Impact and Job Creation

The economic implications of this massive infrastructure project are substantial for the region and the entire UK automotive sector. When fully operational, the gigafactory will create approximately 4,000 jobs, with the initial phase beginning with 1,500 positions in 2027.

During the construction phase, which is expected to span two years, employment numbers will steadily increase:

- 500 workers on site by the end of 2025

- 2,000 construction workers by 2026

- 1,500 operational jobs created in 2027

- 4,000 total jobs when the facility reaches full capacity

The gigafactory’s economic footprint extends beyond direct employment, with Agratas projecting contributions worth “hundreds of millions” to the local economy through supply chains, services, and community investment.

UK Battery Production: Meeting the Demands of an Electrified Future

Situated on the 616-acre former Royal Ordnance Factory site near Junction 23 of the M5 in Somerset, this facility represents a cornerstone of Britain’s EV manufacturing strategy. Once running at full capacity, the plant will produce an impressive 40 GWh of battery cells annually, sufficient to power approximately 500,000 passenger vehicles.

Initially, the batteries produced will supply vehicles like Range Rover, Defender, and Jaguar brands. However, the long-term vision includes providing batteries to other car manufacturers and expanding into commercial energy storage solutions.

By the early 2030s, Agratas estimates the gigafactory could fulfill up to 40% of all electric vehicle battery requirements for the UK domestic market, positioning the country as a significant player in the global EV supply chain.

Sustainable Design: Optimizing for Environmental Performance

The redesigned factory footprint demonstrates Agratas’ commitment to sustainability. By implementing cutting-edge technologies from various countries, the company has achieved an optimal solution that reduces the building size while maintaining production targets.

“We looked at cutting-edge technologies from lots of different countries and we managed to find an optimal solution that allowed us to reduce the building size by around 84 metres,” Weber explained. “It reduces energy and water consumption along with our carbon footprint.”

The construction process itself showcases engineering innovation, with more than 16,000 concrete piles driven vertically into the ground to stabilize the factory’s foundations on the massive site.

Government Support for UK EV Manufacturing

The UK government has played a crucial role in securing this investment, offering what has been described as a “large” incentive package to ensure the plant was sited in Britain. These subsidies are reportedly worth hundreds of millions of pounds, likely structured as cash grants, energy cost discounts, and funding for training and research.

A Department for Transport spokesperson highlighted the government’s broader commitment to electrification: “We’re investing over £2.3 billion to support industry and consumers making the switch, tapping into a multibillion-pound industry that will create high-paid jobs for decades to come, make the UK a clean energy superpower, and secure Britain’s future.”

The Future of UK Automotive Manufacturing

As one of Europe’s largest gigafactories, this project represents far more than just a manufacturing facility. It symbolizes the UK’s determination to remain at the forefront of automotive innovation despite post-Brexit challenges and global market uncertainties.

With one in four cars sold in February being electric and a record 382,000 EVs sold last year (the highest in Europe), the UK is positioning itself as a leader in the transition to sustainable transportation. The Agratas gigafactory will be instrumental in supporting this growth trajectory, providing the battery technology essential for the next generation of British-built electric vehicles.

This landmark investment not only secures thousands of jobs but also establishes a critical foundation for the UK’s ambitions to become a clean energy superpower in the decades ahead.